GFRP Rebar vs Steel Reinforcement: A Comprehensive Comparisontest

Oftentimes, it has been taken considered that the comparison between GFRP (Glass Fiber Reinforced Polymer) rebar and the traditional steel reinforcement is regarded as a huge matter of debate within the construction and civil engineering industries. In respect to the same, both are discussed widely over the different parameters, including strength, durability, cost, eco-balance, among others, so that a more substantiated selection could be made.

This article sheds light on how and where to substitute traditional steel rebar (B500 grade) with fiberglass rebar, which possesses a tensile strength of 1100 MPa and a modulus of elasticity >50 GPa.

Understanding the Basic Difference

Oftentimes, it has been taken considered that the comparison between GFRP (Glass Fiber Reinforced Polymer) rebar and the traditional steel reinforcement is regarded as a huge matter of debate within the construction and civil engineering industries. In respect to the same, both are discussed widely over the different parameters, including strength, durability, cost, eco-balance, among others, so that a more substantiated selection could be made.

This article sheds light on how and where to substitute traditional steel rebar (B500 grade) with fiberglass rebar, which possesses a tensile strength of 1100 MPa and a modulus of elasticity >50 GPa.

Material

When comparing fiber glass rebar and steel reinforcement rod, a deep understanding of their fundamental properties is important. These properties not only determine the suitability of each rebar type for specific application conditions but also their performance over the lifespan of a construction project.

GFRP (Glass Fiber Reinforced Polymer) rebar

Glass fiber rebar consists of glass fibers embedded within a polymer matrix, typically made from either vinyl ester or epoxy resin. In case of REBARMAT PRO, epoxy matrix is used, to ensure that rebar meets requirements of international building codes and standards for structural (load bearing) and non-load bearing reinforcement. This configuration forms the core of the rebar’s structural capabilities and its resilience against environmental challenges. Within this polymer matrix, the glass fiber reinforcement provides notable tensile strength and rigidity to the rebar.

During its production, glass fibers are drawn through a resin bath, ensuring they are fully impregnated by the polymer. They are then guided through a shaping die to form the rebar’s profile. Following shaping, the material undergoes a curing process also called polymerization, at temperatures ranging from 200 – 250 °C. Later GFRP rebars are cut according to length from 0.5m-300m, depending on application.

Steel reinforcement rods

Steel rods, made from carbon steel across different grades for varying yield strengths, are manufactured by hot rolling steel billets in mills before undergoing twisting or deformation for improved concrete bonding. Additionally, cold forming techniques are used to further enhance surface profile and mechanical properties. Consisting mostly of iron with a slight carbon addition to boost strength and fracture resistance, these rods may also include manganese, silicon, and sometimes chromium and nickel, aimed at improving mechanical properties.

B500A, B500B, and B500C: These are the common grades of reinforcement steel in Europe, with a characteristic yield strength of 500 MPa. The letters A, B, and C indicate the ductility class, with B500B being the most commonly used grade in general construction.

Strength and Performance

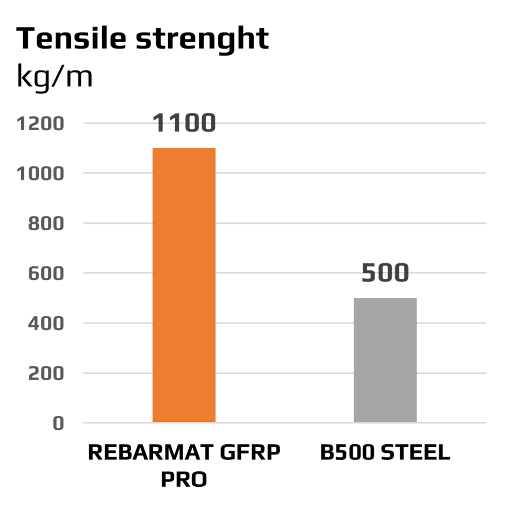

Tensile Strength

Traditional B500 grade steel rebar, a long-standing standard in construction reinforcement, delivers a tensile strength of around 500 MPa. The GFRP rebar however is one of those clear competitors offering tensile strength of 1000 MPa or even, most often, stronger.

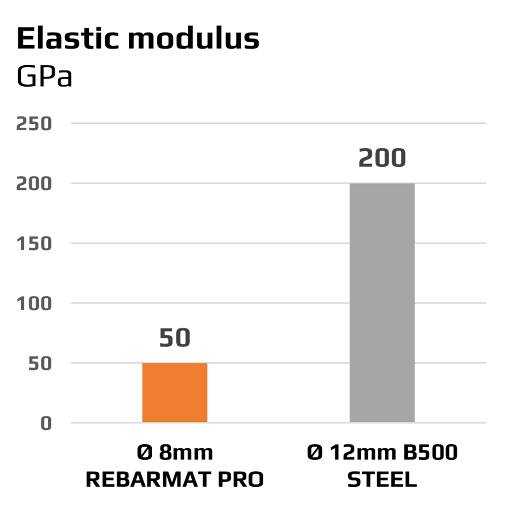

Modulus of Elasticity (Young’s Modulus)

This is one of the most discussed mechanical property of Fiberglass Reinforced Polymer (FRP) rebar, including its subtype, GFRP rebars, that attracts attention of most structural engineers. A higher Young’s Modulus indicates that the material is stiffer, meaning it deforms less under a given load. In contrast, a lower Young’s Modulus suggests that the material is less stiff, meaning it deforms more under the same load. With B500 reinforcement steel rebar this value is 200 GPa, compared to 50-55 GPa of fiberglass rebar. It clearly shows that steel is stiffer and deforms less under the same load. But this lower stiffness of GFRP rebars offers unique advantages in certain applications. For instance, the reduced stiffness can lead to a more flexible structure that can spread energy more effectively under dynamic loads. This flexibility allows for a distribution of stresses that might be beneficial in preventing failure modes associated with brittle fracture.

Moreover, while GFRP rebars may deform more under load due to their lower Young’s Modulus, this does not directly translate to a lack of structural integrity or safety. Design and engineering principles allow for the accommodation of these characteristics in the overall structural design, ensuring that the final structure meets all required safety and performance standards.

Durability and Maintenance

Corrosion Resistance

GFRP (Glass Fiber Reinforced Polymer) rebar is notably resistant to corrosive influences, making it ideal for environments prone to moisture or chemical attack. These conditions are classified as aggressive environment and are specified in Eurocode 2 (Design of Concrete Structures – Part 1-1: General Rules and Rules for Buildings). Unlike steel, which requires specific protection measures to prevent rust and degradation, GFRP remains unaffected by such conditions. These environments typically include exposure to moisture, temperature fluctuations, and harmful chemicals either in the soil or from atmospheric sources. These factors can accelerate the degradation of concrete and the corrosion of steel reinforcement. Therefore, GFRP rebar offers a durable alternative in settings where steel rebar’s susceptibility to corrosion could compromise structural integrity.

Main exposure classes according to Eurocode 2 (EN 1992-1-1) are:

- XC – Exposure to Carbonation

- XD – Exposure to Chlorides other than from sea

- XS – Exposure to Chlorides from sea water

- XF – Exposure to Freeze-thaw attack

- XA – Exposure to Chemical Attack

- XM – Exposure to Mechanical Abrasion

General problem with B500 steel reinforcement bar is oxidation. When oxidation of steel progressing, bond with concrete decreases, making structures prone to cracking and eventually failure. According to EC2, there are different concrete cover that is crucial for protecting reinforcement steel within concrete structures. The concrete cover is the distance between the surface of the reinforcement and the outer surface of the concrete.

With GFRP, concrete cover in most classes can be considered to be minimal. Making huge reduction in concrete use, weight and overall project budget.

GFRP offers advantages in corrosion resistance and potentially reduced concrete cover in certain applications, the specific requirements for concrete cover should always be determined based on detailed design analysis and local regulations, taking into account all relevant factors including but not limited to corrosion risk.

Lifespan

The lifespan of GFRP (Glass Fiber Reinforced Polymer) rebar in concrete structures significantly surpasses that of traditional steel rebar, especially in corrosive environments. This extended lifespan is primarily due to GFRP’s inherent resistance to humid, salts, carbon dioxide, acids, sulfates and alkaline environment, which is a leading cause of degradation in steel rebar and consequently, in reinforced concrete structures.

While the exact lifespan can vary based on environmental conditions and the specific application, GFRP rebar generally has the potential to extend the service life of a concrete structure to 100 years or more, compared to the 50 to 75 years often expected with steel rebar in non-corrosive environments. In highly corrosive environments, the lifespan of steel-reinforced structures may be significantly reduced without substantial protective measures.

The durability of GFRP rebar contributes to lower maintenance costs over the structure’s lifespan. Structures that utilize GFRP rebar may require less frequent repair and maintenance related to corrosion, which can also lead to lower lifecycle costs compared to structures reinforced with steel.

Besides the direct benefits in terms of lifespan and maintenance, using GFRP rebar also contributes to sustainability by reducing the need for repairs and replacements, thereby minimizing the environmental impact associated with construction activities and materials production over time.

Economic Evaluation

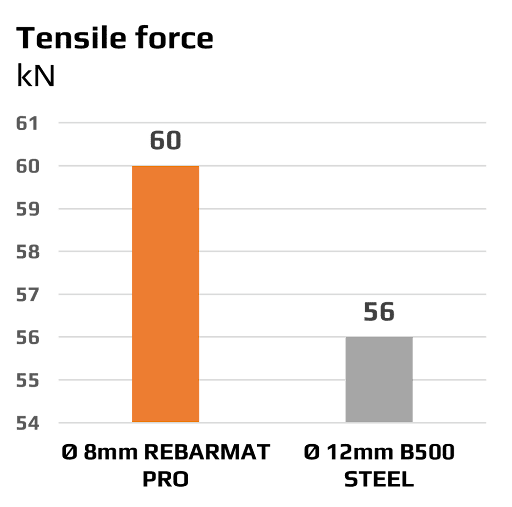

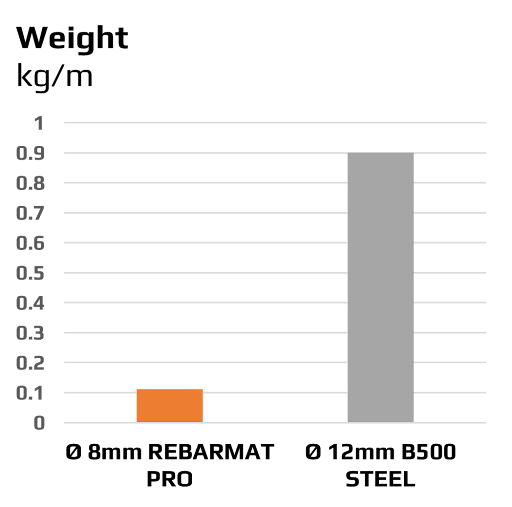

Comparing directly in terms of geometrical characteristics and based on a 1m length, GFRP rebars have higher initial costs. But let’s analyse it deeper. The performance of concrete reinforcement materials is primarily evaluated based on their strength per unit area (mm²) or, simply put, the force they can withstand.

| 12mm B500 steel rebar | 8mm REBAMAT PRO GFRP | |

|---|---|---|

| Weight | 0.89Kg | 0.112Kg |

| Tensile force | 56kN | 60kN |

| Price per tonne | 800Eur | 5000Eur |

| Price per meter | 0.72EUR/m | 0.56EUR/m |

Initial substitution of 12mm B500 steel rebar with 8mm REBAMAT PRO GFRP is particularly relevant to flatwork applications, such as floors and pavements, where the depth of concrete can limit rebar size. It’s important to note that this simplified analysis does not take into account other factors such as durability, maintenance costs, lifespan, and application-specific requirements, which can significantly influence the overall economic comparison between GFRP and steel rebar in construction projects.

In most scenarios, GFRP (Glass Fiber Reinforced Polymer) rebar, despite its higher price per tonne, can offer cost efficiencies due to its higher tensile strength and lower weight. This efficiency can make GFRP an attractive option for certain projects, particularly where material performance and long-term durability are prioritized. While the initial purchase price of GFRP is higher than that of steel reinforcement, these superior properties can result in a reduced overall material requirement, potentially offsetting the higher cost. However, it’s crucial to acknowledge that the upfront cost represents just one component of a comprehensive financial analysis. The long-term benefits and savings associated with reduced maintenance and longer lifespan due to GFRP’s corrosion resistance significantly contribute to its value, making it a financially viable option over the project’s life.

Environmental and Ethical Considerations

Carbon Footprint

GFRP stands out as a material with a lower carbon footprint, attributed to its durability and the minimal need for replacement. While steel rebar has seen significant advancements in recycling, enhancing its sustainability profile, the recycling process is complex, requiring considerable labor, energy, and resources, which raises questions about its overall sustainability. When considering the production processes of both materials, GFRP emerges as the more environmentally friendly option due to significant improvements in its manufacturing methods, reducing its environmental impact even before reaching the consumer.

Material Traceability

The production processes and sustainability of both GFRP and steel are under continuous inspection. GFRP’s manufacturing is generally cleaner, with a higher potential for recyclability that may even contribute to enhancing concrete through the grinding process. Steel manufacturing also strives for a positive environmental impact and is subject to ongoing sustainability and ethical improvements. However, a notable difference lies in material traceability; GFRP producers often offer greater transparency in their supply chain compared to major steel suppliers, providing an edge in terms of sustainability and ethical practices. Therefore, in terms of environmental impact and material traceability, GFRP rebars demonstrate a noticeable advantage.

Application Examples

Flatwork and ground applications

GFRP stands out as an ideal material for ground floor installations, offering substantial benefits across a diverse range of applications. Its unique properties make it especially suitable for:

- Residential Projects: Elevates the durability and longevity of home foundations, driveways, and walkways.

- Patios and Landscaping: Offers an aesthetically pleasing and practical solution for outdoor living spaces and garden pathways.

- Parking Lots: Provides durable, long-lasting support capable of handling heavy vehicular traffic.

- Commercial Flooring: Essential for high-load-bearing floors in warehouses, retail spaces, and industrial facilities, where strength and maintenance-free longevity are critical.

- Foundations: Enhances the structural integrity of buildings with its strong, corrosion-resistant framework.

- Agricultural Facilities: Ideal for barn floors, greenhouses, and storage buildings, contributing to a cleaner and more durable environment.

The ease of integration into engineering projects, due to its compatibility with existing designs without the need for recalculations, alongside the straightforward handling and installation process, makes GFRP a compelling choice for constructors and engineers alike. Its application in these areas not only streamlines construction efforts but also ensures a blend of durability, performance, and cost-effectiveness.

Precast industry

For Marine and Coastal Projects, GFRP (Glass Fiber Reinforced Polymer) rebar emerges as an exemplary choice, distinguished by its superior resistance to the corrosive elements inherent in these environments. Its resilience and durability in facing saltwater, moisture, and chemical exposure make it particularly advantageous for a wide array of applications, including:

- Seawalls and Breakwaters: Offers enhanced longevity and reduced maintenance for structures that act as the first line of defense against coastal erosion and storm surge impacts.

- Docks and Piers: Ensures a durable, corrosion-resistant foundation for marine structures subject to constant immersion or splashing by saltwater, extending their service life significantly.

- Marine Bridges: Provides a reliable reinforcing solution for bridges exposed to marine spray, contributing to structural integrity over extended periods.

- Coastal Walkways: Ideal for pedestrian pathways along beachfronts, where exposure to salt and moisture is constant, GFRP helps maintain safety and aesthetics with minimal upkeep.

- Marinas: Supports the infrastructure of marina facilities, from floating docks to mooring posts, where water resistance and buoyancy are critical considerations.

- Water Treatment Facilities: In coastal water treatment and desalination plants, where structures are exposed to highly corrosive environments, GFRP ensures the durability and reliability of containment and processing units.

The utilization of GFRP in these settings not only capitalizes on its corrosion resistance but also leverages its lightweight, ease of installation, and high tensile strength, making it a preferred material for engineers and architects aiming to optimize the longevity and resilience of marine and coastal projects. Its adoption signifies a proactive approach to overcoming the challenges posed by harsh marine environments, ensuring the sustainability and structural integrity of vital infrastructure.

In terms of use cases, this is a small list of applications, where GFRP bars benefit over steel reinforcement bars.

Final thoughts

GFRP rebar offers significant advantages in terms of strength, durability, economic efficiency, and environmental sustainability, making it a compelling alternative to traditional steel reinforcement in specific applications, especially those susceptible to corrosion or requiring material longevity.

However, the choice between GFRP and steel reinforcement should be informed by specific project requirements, including environmental conditions, load-bearing needs, and cost considerations. The growing adoption of GFRP in various sectors highlights its potential to enhance the durability and sustainability of construction projects, despite its higher initial cost compared to traditional steel rebar.